Profile

Surface Treatment Company (STC) is a world class supplier in thermal, thermo-chemical and surface treatments of mechanical components using several state-of-the-art production processes.

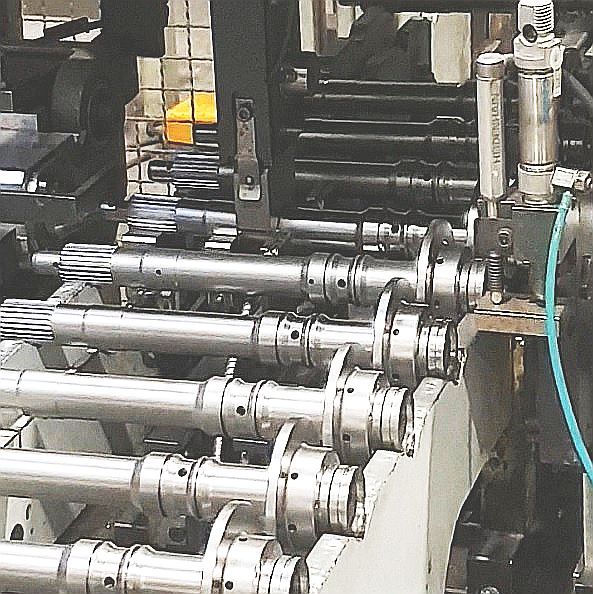

During the years, STC has installed a wide range of furnaces and auxiliary treatment machinery. The furnaces can be used for case hardening, gas nitriding and reheating combined with full automatic press hardening. The induction machines are available with HF and MF generators. Auxiliary treatments can consist of shot blasting or fully automatic straightening with crack detection of shafts. STC also provides metallurgical lab work with hardness testers, microscopes and part cleanliness measurement equipment.

Thermal and thermo-chemical treatments

Carburizing and carbonitriding

Chamber furnaces

- 4 x LLF8 : max 1050 °C, 910x1220x910mm, 1300 kg/load

- 4 x LLF10 : max 1050°C, 1220x1500x910mm, 2000 kg/load

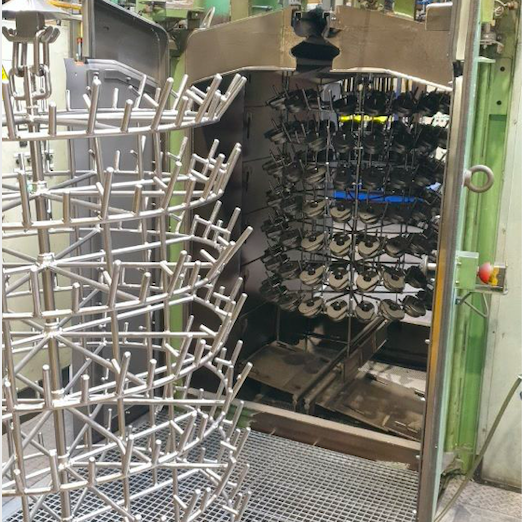

Nitriding and nitrocarburizing

4x pit furnaces: max 700 °C, diam 1100mmx1800mm, 3000 kg/load

Die quenching, quench & temper, annealing

max dimensions of product: 400x330mm

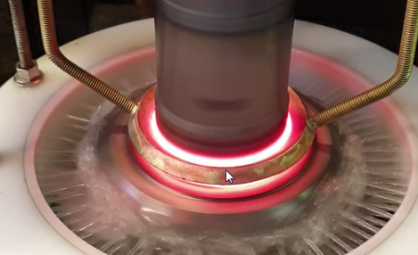

Induction hardening HF & MF

Induction heating combined with press quench

Processes:

Processes: Auxiliary processes

- Sub-zero treatment

-

Glass pearl, steel or stainless steel shot blasting

-

Automatic masking

- Magnetic particle inspection

-

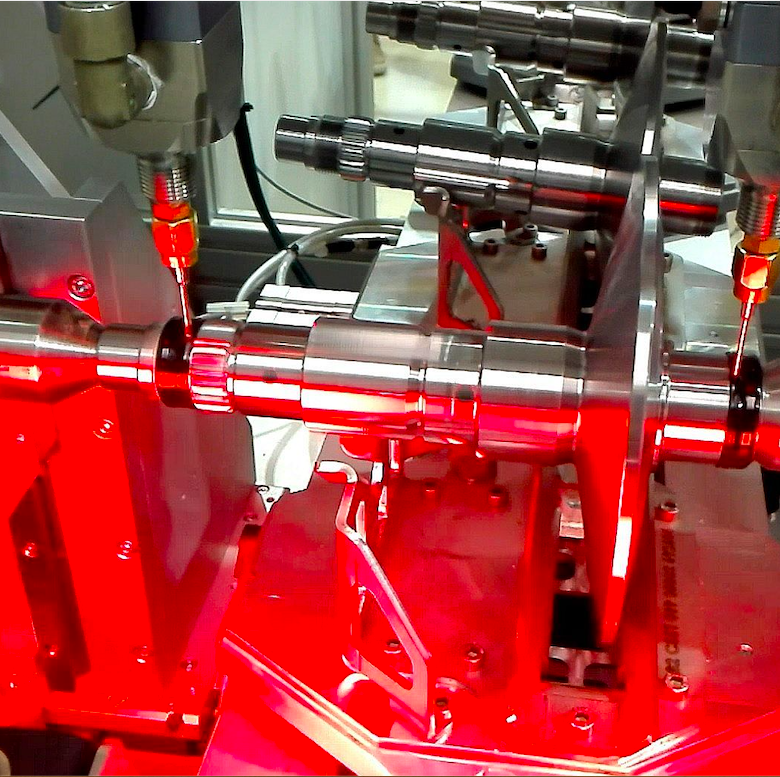

Automatic or manual straightening

Processes Material Technology Centre

Material Laboratory

- Microscopy

- Mechanical testing

- Chemical (GD-OES, ICP, …)

- NDT (MPI, eddy current, penetrant, grinding burns)

Project Engineering

- Support in the field of material technology

- Project: studies, development, realization

- Training

- Technology watch: materials – processes – environmental care

Clients

Contact us

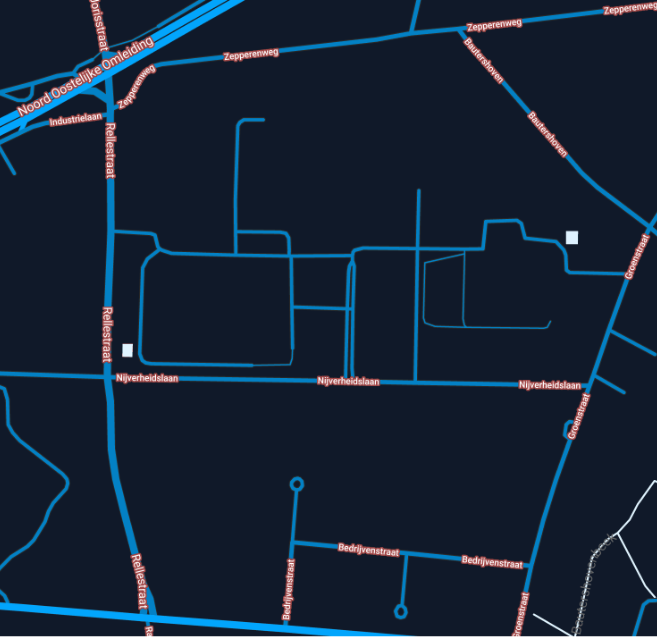

- Nijverheidslaan 5420

3800 Sint-Truiden, Belgium - stc@vcst.be

- tel: +32-11670296